Linyi Guoyu Machinery Co.Ltd

Pay attention to work details and improve service quality

Linyi Guoyu Machinery Co.Ltd

Pay attention to work details and improve service quality

Linyi Guoyu Machinery Co.Ltd

Pay attention to work details and improve service quality

Linyi Guoyu Machinery Co.Ltd

Pay attention to work details and improve service quality

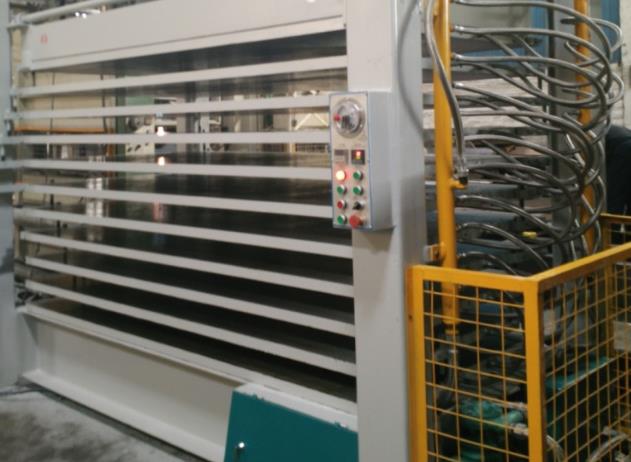

Hot press is a kind of equipment that can heat two parts coated with solder flux in advance to make the solder melt and flow. After curing, a permanent electrical mechanical connection device is formed between the parts and the solder. According to different products, heating rate can be selected. Titanium alloy indenter ensures average temperature, fast temperature rise and long service life. The ram is specially designed to be horizontally adjustable to ensure that the components are pressed evenly. Temperature numerical control, clear and precise. Equipped with digital pressure gauge, pressure range can be preset.

The press is a safe clothing making method of heating and pressurizing. It is mainly suitable for the hot melting of zipper double-sided adhesive tape, bag cover and pocket, as well as hot stamping and hot stamping.

The main technical solutions are as follows:

The lever installed in the body of the hot press can wind the lever shaft and swing back and forth in the equipment body. A group of hot pressing parts are installed at the other end of the lever. The lever and manual are connected together. The switch is installed on the same side of the manual device. Then the pneumatic equipment connected with the switch is fixed to the body of the hot press. The operation mode of the hot press is very simple. The operator can control the cylinder through the manual device of the equipment. When the hot pressing plate and the working table reach a certain distance, the pneumatic device can be turned on, which greatly improves the hot hand problem of the hot press.

The equipment structure composed of heat reflecting material, working beam, heat insulation material, hot pressing plate, cooling device and circulating pump, as well as heat insulation, heat reflection and cooling water circulation used under heating conditions have greatly improved the technical achievements of hot pressing equipment. On the one hand, it saves a lot of heat energy, on the other hand, it ensures the hot pressing plate to work In this way, the temperature of the upper and lower panels of the equipment can be kept consistent, which greatly improves the operation accuracy of the hot plate. The main structure of the automatic hot press is the track, the upper and lower mold and the related transmission device.

Hot press piston care methods:

The direct cause of oil leakage is the wear or incorrect installation of rubber seal ring, and the indirect reason is the damage of piston surface or incorrect position. When the piston surface is good, the service life of the rubber seal ring installed correctly can reach more than 6 months. The main reason of piston surface damage is that the oil contains sand and other impurities. Once the piston surface is scratched, the scar will expand and deepen rapidly under the strong grinding of high pressure oil leakage. During the pressure process, the acid waste water extruded from the wet plate will corrode the piston surface. The higher the temperature is, the greater the corrosion is, especially when the hard protective layer on the piston surface has scars.

In addition, the small wood fiber in the extruded wastewater is also easy to squeeze into the seal ring and piston, affecting the sealing effect. The hydraulic oil should be kept clean and the oil pool should be covered and sealed. The filter screen of oil pump suction pipe shall be kept intact, and it shall be replaced in time if it is damaged. During maintenance, the sediment in the pool should be removed, and the oil should be used after clarification or filtration (the emulsion should be completely replaced). This is also very important for the protection of oil pumps and precision valves. The water spray pipe around the piston is used to wash the piston to avoid corrosion by acid waste water and keep it clean. In areas with high temperature, it can also reduce the temperature of the piston.

The eccentric wear of piston is also one of the reasons for surface abrasion and seal ring wear or extrusion. It is caused by the uneven thickness of wet slab and eccentric load when the press is pressurized. The fitting accuracy of piston and cylinder liner is d (DC4), and excessive clearance will cause eccentric wear. For the oil cylinder with frequent oil leakage, the piston should be lifted out to check the surface condition, especially the part of the sealing position at the highest pressure, which should be replaced when the damage is serious.

PLYWOOD MACHINE EQUIPMENT

PLYWOOD MACHINE EQUIPMENT

Veneer veneer cutting machine is one of the main products supplied by Linyi Guoyu Machinery Co., Ltd. at the same time, the company also supplies a variety of plywood production machinery, such as hot press, planking machine, lifting table, etc.

Contact: Luna Jiang WhatsApp/WeChat: +86 13385391681

Telphone: +86 13385391681 Address: Yitang Town,Lanshan District Linyi city,Shandong Province,China

©All rights reserved by Linyi Guoyu Machinery Co., Ltd